Flow measurement

Basic Flow Concepts

It’s great if you can understand the flow profile of your application or the way the flow of a fluid behaves in a pipeline (based on its velocity and viscosity) because it’s from this information you can decide which of the many different types of flow meters are best suited to your application.

Flow measurement is the quantification of bulk fluid movement.

Two areas that the flow profile is based on are:

- Knowing your fluid

- Knowing your flow type

Know your fluid

It is important to know what you are measuring e.g. air, water, milk, oil, sewerage etc this is because due to their differing viscosities every gas or fluid will behave differently as they flow through a pipe.

The flow profile of a fluid will vary according to whether it is Newtonian or non-Newtonian.

Examples of Newtonian fluids include milk, water, sugar solutions and mineral oils.

Examples of non-Newtonian fluids include paints, cement slurry, shampoos, blood, toothpaste and yoghurt.

Newtonian fluids have a tendency to ‘stick’ to the pipe walls, which means the liquid moves more slowly at the sides of the pipe than in the middle.

Newtonian liquids have a directly proportional relationship between the pressure of the liquid flowing through and the resistance caused by the fluid sticking to the pipe walls.

The behaviour of non-Newtonian fluids is harder to predict, as there is no relationship between pressure and resistance – the behaviour varies either with time or as a consequence of changes in the shear force inflicted by resistance from the pipe wall

Know your flow

There are three types of flow and these are linked to the velocity of the fluid.

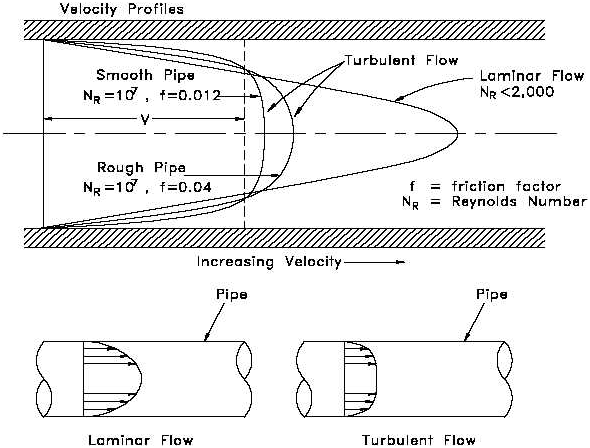

Laminar flow

- Predictable type of flow

- Occurs at stable, low flow rates

- The fluid settles into streamlined tiers

- Tiers are prevented from merging by viscous forces within the liquid

- Move in the same direction at a constant speed

- Parabolic in form

Transitional flow

- Occurs when an increase in velocity causes distortions in the flow

- This leads to mixing of the tiers within the fluid

- Exhibits both laminar and turbulent characteristics at different points throughout the pipeline

- The profile is unstable and complex - can be parabolic as in laminar flow, flatter as in turbulent flow or a combination of both

Turbulent flow

- Occurs at faster flow rates

- Eddies and whorls’ form mass distortions & randomly fragment causing blending of the tiers within the fluid

- Fully Developed Turbulent Profiles are not fixed

- Change with the Reynolds number.

- Found in many applications

- Is the preferred condition for a flow meter as flow meters are all calibrated in these conditions so provides the best situation for the flow meter to achieve repeatable and accurate flow measurements.

By profiling the flow of a fluid through a pipeline, you can find out how it is likely to behave and from there you can narrow down your choice to a flow meter that best suits your application.